Some Known Details About 24??media

Some Known Details About 24??media

Blog Article

24??media Things To Know Before You Get This

Table of ContentsGetting My 24??media To WorkThe smart Trick of 24??media That Nobody is DiscussingThe smart Trick of 24??media That Nobody is Talking About24??media Things To Know Before You BuyAll about 24??media

Advancements in print innovation are altering the interactions playing area when it concerns high quality, affordability and sophisticated capabilities. Countered printing and digital printing are the significant procedures whereby print jobs are undertaken both utilizing four-color printing approaches. Each choice has its advantages, supplying different strategies to satisfy the demands of diverse manufacturing jobs.

Generally, this has actually been the most regular technique for exactly preserving shade matches, making it perfect for print runs that just call for static printing such as pre-printed kinds, sales brochures, leaflets, calling card, and mass postcard mailings. Nevertheless, because of the static nature of litho printing, it is not excellent for variable print items that will certainly be mailed to specific recipients such as statements, letters, and individualized postcards.

24??media Fundamentals Explained

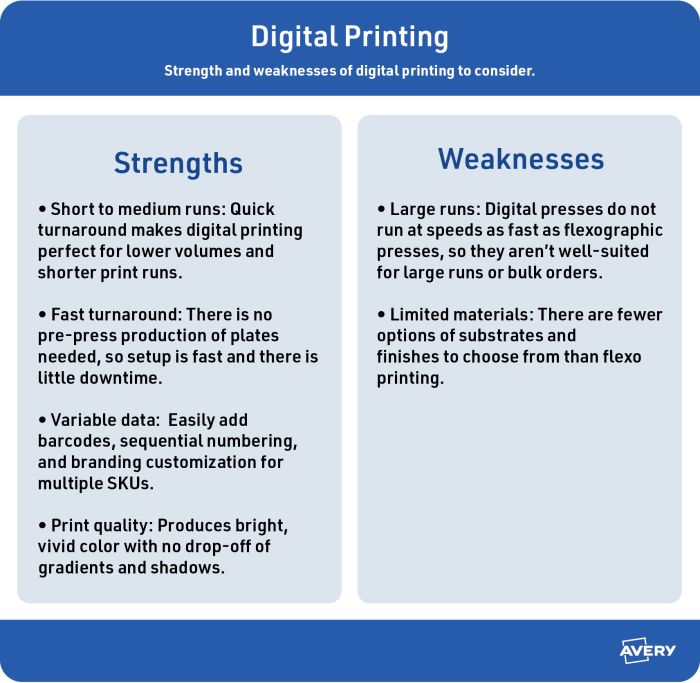

The most recent advancements in print technology are assisting to bring many of balanced out's benefits right into the electronic printing world genuinely transforming the face of contemporary printing! There are some vital distinctions between Offset Printing and Digital Printing (Stickers). This guide reveals the benefits and drawbacks of each printing approach. There is an obvious and expanding variety of benefits to using the digital print process.

Today's electronic print equipment is among the most cutting-edge on the marketplace. Below are a few of the biggest advantages of utilizing electronic printing: control the electronic print room, with full-color printing finished in one process and flawlessly published directly from a print data. Without an extensive set-up process, the calibration time of a certain task is reduced, adding to quicker print time and general distribution.

The inkjet printing procedure has assisted to change the industry in addition to the high quality and speed of the output. The current inkjet innovation can print on traditional balanced out stocks with dull, silk, and glossy surfaces. High-grade digital print coupled with software-managed shade administration methods includes optimum worth to print items and makes manufacturing processes extra dependable than countered.

The smart Trick of 24??media That Nobody is Talking About

(https://dzone.com/users/5288202/za24media.html)

Precise quantities of ink and printer toner are utilized to prevent waste. Environmentally friendly and biodegradable inks and printer toners are additionally available for more sustainable printing. Digital print also removes the demand to clean plates or blankets with damaging chemicals at the end of the printing procedure. As the quality of electronic print services boosts, the benefits end up being increasingly noticeable and advantageous.

Variable data aids companies webpage reach their exact customers and audience with uniquely-created and individualized material. As technology enhances, the quality of electronic printing has actually come to be second-to-none, with greater information, shade match capabilities and general precision. Without the demand to clean plates or utilize excess ink, digital printing is additionally less wasteful and usually more eco pleasant.

Typical printing approaches, such as countered lithography ("countered") and flexography ("flexo"), include multiple make-ready steps to move an original picture to a substratum. These methods need the manufacturing of a collection of plates placed on a cyndrical tube to move ink that forms the desired picture when incorporated on paperboard and other packaging materials. Point of sale stands.

About 24??media

Digital printing, with less relocating items, is more dexterous than balanced out in this regard.

It's a means to blend your product packaging and marketing methods. Decreased set-up time saves cash on the front end. And since these are not large mass orders, smaller organizations can pay for to publish without needing to fulfill the higher and a lot more expensive print limits of traditional printing. Digital printing helps safeguard your brand versus counterfeiting by incorporating overt and hidden services on your packaging.

Make certain you team up with a printing and product packaging companion that has the right qualifications. While eleventh-hour printing and personalization are a big advantage, digital might not always be the very best technique for you. Offset printing has the advantage of cost-effectiveness with large print runs, particularly those with sophisticated decorative impacts and specialized coverings.

Fascination About 24??media

Lithographic presses make use of two print platesa positive and a negativeto transfer high-grade color graphics onto a suitable substratum. The favorable plate, with its smooth surface area, draws in oil-based inks and pushes back water. In contrast, the negative plate, with its harsh appearance, absorbs water and wards off oil. Rubber rollers are after that made use of to move the photo from the plate to the corrugated surface.

Corrugated paper can often verify to be a difficult surface to publish on, yet Litho prints to a different surface area and is then laminated flooring to it, making it very easy to print high-grade pictures. It can be incredibly constant, also for long terms. As a matter of fact, the more you publish, the cheaper the expenses become for Litho.

What Litho doesn't give you is precisely what Digital does, modification. Costly established up Longer turn-around No Variable Information Printing Smaller color gamut, colors can be less intense Digital printing is the procedure of printing electronic images directly onto the corrugated substratum utilizing a single-pass, direct-to-corrugate method.

Report this page